Educational February 2021

At Sol by Sunna Design, we’re proud to be able to provide municipalities with reliable solar street lighting to illuminate their streets and parks, bring needed light to remote areas, and meet sustainability initiatives. Our lights are field-proven to meet industry-standard light levels reliably for years with minimal maintenance. How do we do it? Along with an innovative system design and purpose-built, efficient energy management, we put extensive effort into ensuring the solar and batteries in our systems are properly sized.

A properly-sized solar light means the system has just enough solar wattage, battery capacity, and LED fixture efficiency to operate at the project-required light levels every night for multiple years—all while providing backup power to last in unpredictable weather and without adding unnecessary solar panels or batteries. It is the Goldilocks solution: not too few solar components to make the system die prematurely, and not too many to make the system needlessly expensive.

Here are three key factors a properly sized, reliable solar street light depends on: a healthy array-to-load ratio, sufficient battery capacity and backup power, and an efficient LED fixture and operating profile.

If you want to explore proper sizing in detail, download our Ultimate Solar Lighting Guide. This expansive guide describes how solar lighting works, why clients choose solar and examines product specifications and comparisons.

Properly sizing a reliable solar light requires balancing many different inputs and outputs. These include analyzing the project location, specifying sufficient solar array wattage, selecting the right battery chemistry and capacity, choosing an efficient LED fixture and operating schedule, retaining ample battery backup power in case of poor weather, and others.

The first key factor to consider is the array-to-load ratio (ALR)—a simple, golden rule for sizing solar lighting systems. It is the ratio of energy generated by the solar panels (known as the “array,” or energy-in) compared to the energy consumed by the light fixture (known as the “load,” or energy-out). A healthy ALR means a lighting system collects more solar energy during the day than it expends at night when the light turns on.

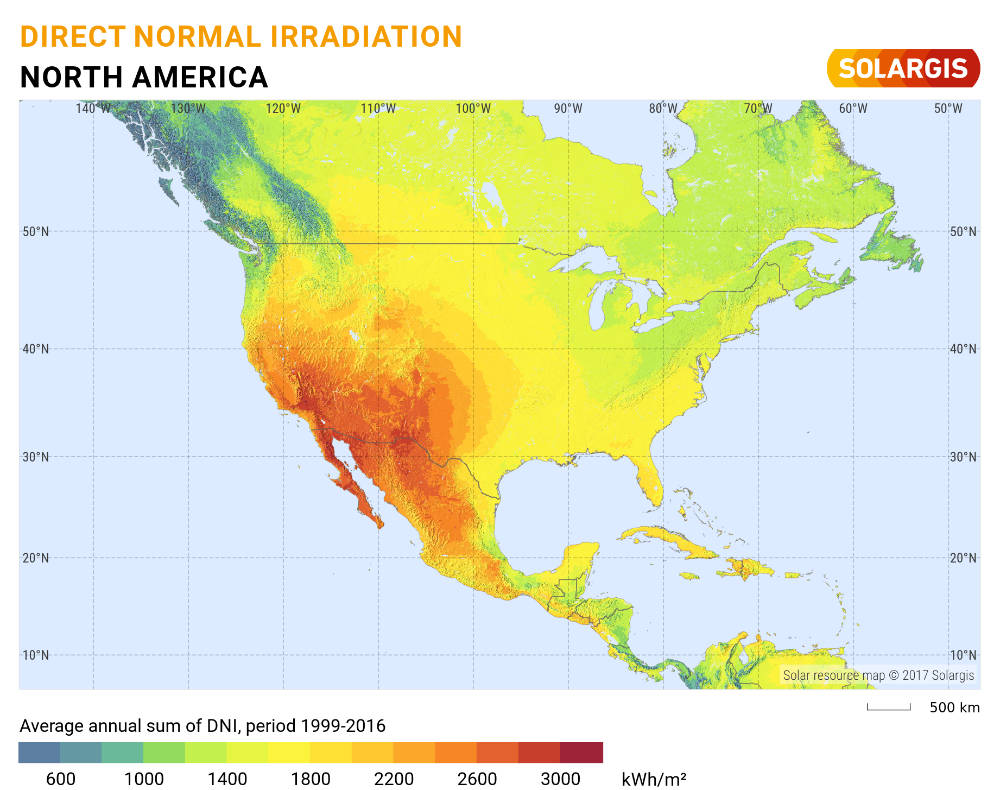

The location should always be the first factor considered for any solar lighting project. Different latitudes have different amounts of incoming solar energy: this is known as solar insolation and is measured with kWh/m2/day. The chart below shows the average annual daily solar energy across the Americas. As you can see, southern areas like California receive far more solar energy per day than northern regions like Alaska. This means that compared to their southern counterparts, northern locations will generally require a larger solar array and additional batteries to meet the same light levels.

Knowing where a project is located helps to determine the prospective system’s solar wattage and battery capacity. Failing to take location into account can lead to a system that can’t sustain the light load and dies prematurely or lead to a more costly one with redundant solar capacity. Therefore location should always be the first factor to consider.

Sometimes, manufacturers may add extra or larger solar panels to conceal poor energy management or an improperly sized system. Unfortunately, there is such a thing as too much solar. An overly sized system is more expensive to ship and install. It increases the wind load on the panels, requiring larger, costlier poles to compensate, and looks bulky and unappealing depending on local urban design aesthetics. Read our article on the golden rules of solar sizing to learn more.

A solar street light lives or dies by its batteries, and one concern a prospective customer may have is a battery that dies prematurely. Premature battery death is almost never due to an inherent flaw in batteries or solar technology. This issue is caused by improper design, poor energy regulation, and, importantly, bad system sizing. When a manufacturer has carefully designed a system, worked on efficient energy management, and sized it with a sufficient solar array wattage and battery capacity, this solar light will run reliably for years.

Solar lighting manufacturers use three main battery types:

Each battery chemistry has its own benefits and drawbacks depending on the application and project requirements. One key difference between the three is their unique depth of discharge profiles.

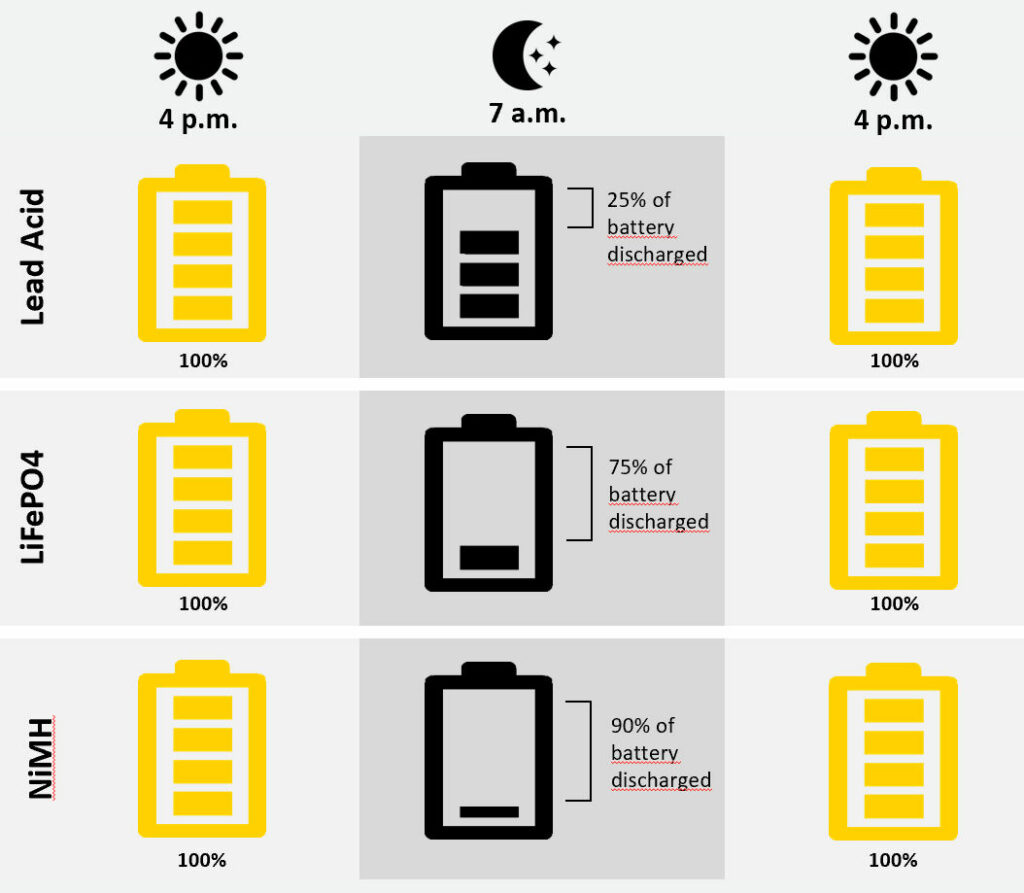

Depth of discharge (also known as DOD) refers to the percentage of the battery’s capacity that is consumed during use. For example, if a solar light runs all night and consumes one-quarter of its battery capacity, that DOD would be 25%.

Understanding depth of discharge is necessary for solar applications because a battery’s cycle life—the number of times a battery can be discharged and then recharged—is extremely dependent on its depth of discharge. Like NiMH and Li-ion, some battery chemistries can safely support being almost fully depleted before needing to be recharged. For other chemistries, such as lead-acid, this level of discharge would dramatically reduce the battery’s cycle life. The chart below shows an example of how much capacity can be safely discharged for each of the three battery types.

While NiMH and Li-ion batteries can safely discharge more every night, the lead-acid battery’s shallower DOD gives it the added benefit of storing more built-in backup power. Building an NiMH or Li-ion-based system with comparable backup power to a lead-acid-based setup would require more batteries and drastically increase the system cost. Ensuring a system has sufficient backup battery power can help improve the light’s performance and longevity when long periods of poor weather are common.

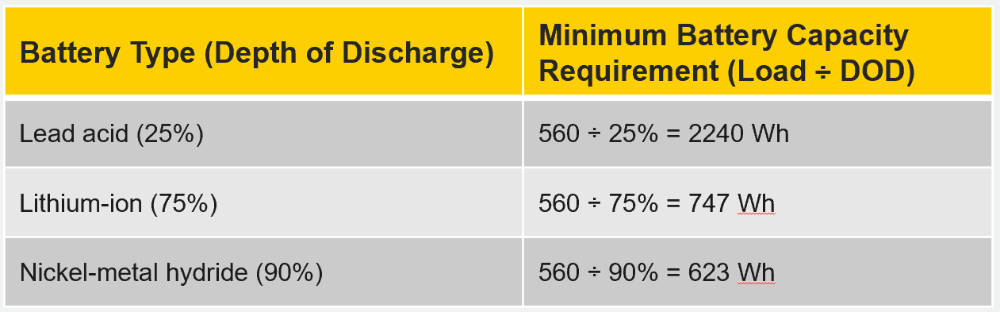

Here’s a quick example of solar battery sizing. For this scenario, imagine our solar light is running a 40-watt LED fixture at 100% output over a 14-hour winter night in Los Angeles. Our system’s total load would be 560 watt-hours per night (40 watts x 14 hours = 560 watt-hours). Assuming perfect weather and the battery is fully charged at the start of the night, what is the minimum capacity for each battery type?

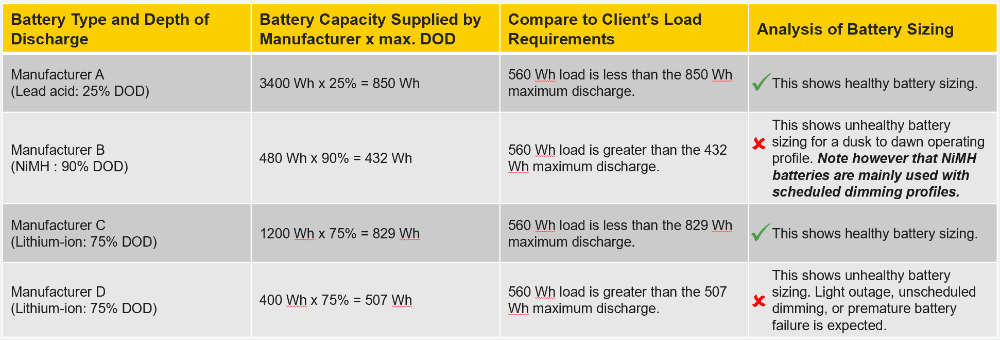

Now that we have an idea of what our minimum battery capacity should be, here are some examples of healthy and low system battery sizing using the battery types mentioned above.

Check out our article on backup power for solar lighting for more information on battery sizing.

Solar devices and LED technology are a perfect match. LED luminaires are the most energy-efficient fixtures available and have allowed solar-outfitted light systems to become dependable and cost-competitive alternatives to traditional commercial lights. Plus, LEDs continue to improve in efficacy, meaning they can provide more units of light (also known as lumens) for less energy than before. For example, current LED fixtures can provide 160 lumens per watt at warm color temperatures like 3000K. This is a welcome innovation in the world of solar system sizing because it enables smaller systems to achieve the same results as larger installs that use lower efficacy fixtures.

Another tool in the solar sizing process is choosing an appropriate operating profile. An operating profile is a schedule that determines when the light fixture turns on and off, as well as if (and when) it needs to dim its light output. These profiles allow manufacturers to tune their systems differently to meet unique power management needs.

Here are some examples of common operating profiles:

Alongside fixture power draw, the operating profile helps calculate nightly energy consumption and is essential for determining the proper system size. Proper sizing is the most important step in building a solar street light to ensure it will operate reliably over the long term. If you want to learn more about the science of solar sizing, check out our infographic here or download our ultimate solar lighting specification guide.